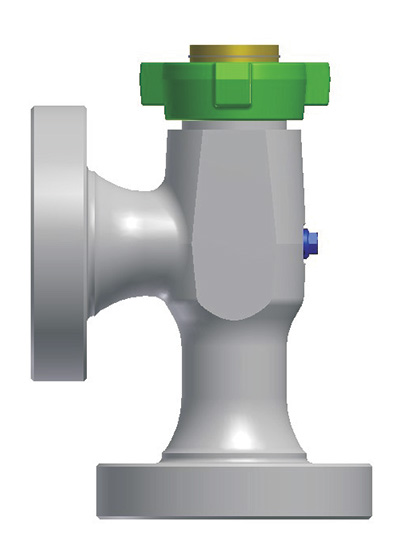

- SIZES: 1" to 16" (25mm to 400mm)

- RATINGS: ASME 600 to 4,500/API 6A 3,000 to 15,000

WHY CHOOSE A SERIES 73 CHOKE VALVE?

- Choke body materials can be of forged, HIPped or cast construction.

- Robust cartridge trim (bi-directional flow option).

- Patented plug/seat design for heavily contaminated flows.

- Solid or balanced plug available.

- Dump tube/sparger (only for bypass to condenser)

- High-grade premium carbide trims for optimum erosion resistance.

- Brick stopper anti-collapse trim available.

- Choose from a wide range of actuator options.

- Seals are resilient and do not suffer from explosive decompression.

- Divides the main flow into many small streams, increasing turbulence and noise peak frequency and maximising the pipe wall transmission loss.

- High energy levels, pressure and velocity are dissipated within the trim - avoiding erosion damage.

- Design of final stage ensures low-velocity non-interacting jets, avoiding unnecessary noise generation in the choke outlet.

- Various trim sizes can be used on different choke body sizes, to suit a wide range of process parameters.

- The inner tungsten carbide control elements are protected from impact damage by the outer cartridge sleeve.

On applications where there is a risk of high sand contamination, the HF-LCV trim design is the ideal choice. It has been independently tested and has proved very successful in some of the most erosive service conditions.

- Premium-grade solid tungsten carbide critical control elements.

- Solid tungsten carbide sacrificial plug nose.

- Shrouded plug seat, protected from the high erosive flow path.

- Hole development dead band - the seating area is removed from the main flow area.

- Stem scrapers prevent migration of sand into the stem seal area.

- Resilient plug seals with scraper rings.

- Metallic 'brick stopper' prevents solid particles impacting directly on the tungsten carbide.

- Optional tungsten carbide wear sleeve.