Weldneck Orifce Flange Assemblies

Weldneck orifice flanges are butt-welded into the pipeline. The inside diameter (or the schedule) of the pipe should be specified when ordering.

PI Controls Europe Weldneck orifice flanges are available in classes 300, 600, 900, 1500 and 2500. Raised face (RF) and ring type joint (RTJ) versions can be supplied.

Bolt sizes, weights and important dimensions of orifce flange assemblies are shown in the following tables.

| Nominal Size | Weldneck Orifce Flanges - 300 lb RF | |||||

| Bolts | Approx. weight (kg) | Dimensions | ||||

| mm | Inches | Bolt Qty | Bolt Sizes | B | A | |

| 25 | 1 | 4 | 5/8” x 5.00” | 9 | 171 | 124 |

| 40 | 1 1/2 | 4 | 3/4” x 5.25” | 13 | 178 | 155 |

| 50 | 2 | 8 | 5/8” x 5.00” | 14 | 178 | 165 |

| 65 | 2 1/2 | 8 | 3/4” x 5.25“ | 18 | 184 | 191 |

| 80 | 3 | 8 | 3/4” x 5.25“ | 21 | 184 | 210 |

| 100 | 4 | 8 | 3/4” 5.25“ | 31 | 190 | 254 |

| 150 | 6 | 12 | 3/4” x 5.25“ | 50 | 206 | 318 |

| 200 | 8 | 12 | 7/8” x 5.75“ | 73 | 229 | 381 |

| 250 | 10 | 16 | 1” x 6.50“ | 100 | 241 | 445 |

| 300 | 12 | 16 | 1 1/8” x 7.00“ | 151 | 266 | 521 |

| 350 | 14 | 20 | 1 1/8” x 7.25“ | 207 | 291 | 584 |

| 400 | 16 | 20 | 1 1/4” x 7.75“ | 275 | 298 | 648 |

| 450 | 18 | 24 | 1 1/4” x 8.00“ | 341 | 324 | 711 |

| 500 | 20 | 24 | 1 1/4” x 8.50“ | 408 | 330 | 775 |

| 600 | 24 | 24 | 1 1/2” x 9.50“ | 604 | 342 | 914 |

| Nominal Size | Weldneck Orifce Flanges - 600 lb RF | |||||

| Bolts | Approx. weight (kg) | Dimensions | ||||

| mm | Inches | Bolt Qty | Bolt Sizes | B | A | |

| 25 | 1 | 4 | 5/8” x 5.00” | 9 | 171 | 124 |

| 40 | 1 1/2 | 4 | 3/4” x 5.25” | 13 | 178 | 155 |

| 50 | 2 | 8 | 5/8” x 5.00” | 14 | 178 | 165 |

| 65 | 2 1/2 | 8 | 3/4” x 5.25“ | 18 | 184 | 191 |

| 80 | 3 | 8 | 3/4” x 5.25“ | 21 | 184 | 210 |

| 100 | 4 | 8 | 7/8” 6.00“ | 41 | 209 | 273 |

| 150 | 6 | 12 | 1” x 7.00“ | 82 | 241 | 356 |

| 200 | 8 | 12 | 1 1/8” x 7.75“ | 124 | 273 | 419 |

| 250 | 10 | 16 | 1 1/4” x 8.75“ | 208 | 311 | 508 |

| 300 | 12 | 20 | 1 1/4” x 9.00“ | 250 | 317 | 559 |

| 350 | 14 | 20 | 1 3/8” x 9.50“ | - | 336 | 603 |

| 400 | 16 | 20 | 1 1/2” x 10.25“ | - | 362 | 686 |

| 450 | 18 | 20 | 1 5/8” x 11.00“ | - | 374 | 743 |

| 500 | 20 | 24 | 1 5/8” x 11.75“ | - | 387 | 813 |

| 600 | 24 | 24 | 1 7/8” x 13.25“ | - | 412 | 940 |

| Nominal Size | Weldneck Orifce Flanges - 900 lb RF | |||||

| Bolts | Approx. weight (kg) | Dimensions | ||||

| mm | Inches | Bolt Qty | Bolt Sizes | B | A | |

| 25 | 1 | 4 | 7/8 x 6.00” | 13 | 171 | 149 |

| 40 | 1 1/2 | 4 | 1” x 6.25” | 18 | 184 | 178 |

| 50 | 2 | 8 | 7/8” x 6.00” | 29 | 209 | 216 |

| 65 | 2 1/2 | 8 | 1” x 6.50” | 41 | 215 | 244 |

| 80 | 3 | 8 | 7/8” x 6.00” | 34 | 209 | 241 |

| 100 | 4 | 8 | 1 1/8” x 7.00” | 59 | 235 | 292 |

| 150 | 6 | 12 | 1 1/8” x 7.75” | 120 | 285 | 381 |

| 200 | 8 | 12 | 1 3/8” x 9.00” | 204 | 330 | 470 |

| 250 | 10 | 16 | 1 3/8” x 9.50” | 291 | 374 | 546 |

| 300 | 12 | 20 | 1 3/8” x 10.25” | 405 | 406 | 610 |

| 350 | 14 | 20 | 1 1/2” x 11.00” | - | 431 | 641 |

| 400 | 16 | 20 | 1 5/8” x 11.50” | - | 438 | 705 |

| 450 | 18 | 20 | 1 7/8 x 13.00” | - | 463 | 787 |

| 500 | 20 | 20 | 2” x 14.00” | - | 501 | 857 |

| 600 | 24 | 20 | 2 1/2” x 17.50” | - | 590 | 1041 |

| Nominal Size | Weldneck Orifce Flanges - 1500 lb RF | |||||

| Bolts | Approx. weight (kg) | Dimensions | ||||

| mm | Inches | Bolt Qty | Bolt Sizes | B | A | |

| 25 | 1 | 4 | 7/8 x 6.00” | 13 | 171 | 149 |

| 40 | 1 1/2 | 4 | 1” x 6.25” | 18 | 184 | 178 |

| 50 | 2 | 8 | 7/8” x 6.00” | 29 | 209 | 216 |

| 65 | 2 1/2 | 8 | 1” x 6.50” | 41 | 215 | 244 |

| 80 | 3 | 8 | 1 1/8” x 7.25” | 58 | 241 | 267 |

| 100 | 4 | 8 | 1 1/4” x 8.00” | 82 | 254 | 311 |

| 150 | 6 | 12 | 1 3/8” x 10.50” | 186 | 349 | 394 |

| 200 | 8 | 12 | 1 5/8” x 11.75” | 306 | 432 | 483 |

| 250 | 10 | 12 | 1 7/8” x 13.50” | 500 | 514 | 584 |

| 300 | 12 | 16 | 2” x 15.00” | 764 | 571 | 673 |

| 350 | 14 | 16 | 2 1/4” x 16.25” | - | 603 | 749 |

| 400 | 16 | 16 | 2 1/2” x 17.75” | - | 628 | 826 |

| 450 | 18 | 16 | 2 3/4” x 19.75” | - | 660 | 914 |

| 500 | 20 | 16 | 3” x 21.50” | - | 717 | 984 |

| 600 | 24 | 16 | 3 1/2” x 24.50” | - | 819 | 1168 |

Slip-On Orifice Flange Assemblies

PI Controls Europe Slip-on orifice flanges are designed to slip over the pipe line before welding.

Slip-on orifice flanges are available in class 300, with a raised face (RF).

| Nominal Size | Slip-On Orifice Flanges - 300 lb RF | |||||

| Bolts | Approx. weight (kg) | Dimensions | ||||

| mm | Inches | Bolt Qty | Bolt Sizes | B | A | |

| 25 | 1 | 4 | 5/8” x 5.00” | 7.5 | 102 | 124 |

| 40 | 1 1/2 | 4 | 3/4” x 5.25” | 9.3 | 102 | 155 |

| 50 | 2 | 8 | 5/8” x 5.00” | 11.5 | 105 | 165 |

| 65 | 2 1/2 | 8 | 3/4” x 5.25” | 15 | 108 | 191 |

| 80 | 3 | 8 | 3/4” x 5.25” | 19 | 111 | 210 |

| 100 | 4 | 8 | 3/4” x 5.25” | 29 | 114 | 254 |

| 150 | 6 | 12 | 3/4” x 5.25” | 50 | 114 | 318 |

| 200 | 8 | 12 | 7/8” s 5.75” | 65 | 130 | 381 |

| 250 | 10 | 16 | 1” x 6.50” | 91 | 139 | 445 |

| 300 | 12 | 16 | 1 1/8” x 7.00” | 133 | 152 | 521 |

| 350 | 14 | 20 | 1 1/8 x 7.25” | 177 | 158 | 584 |

| 400 | 16 | 20 | 1 1/4” x 7.75” | 240 | 171 | 648 |

| 450 | 18 | 24 | 1 1/4” x 8.00” | 323 | 184 | 711 |

| 500 | 20 | 24 | 1 1/4” x 8.50” | 360 | 197 | 775 |

| 600 | 24 | 24 | 1 1/2” x 9.50” | 555 | 219 | 914 |

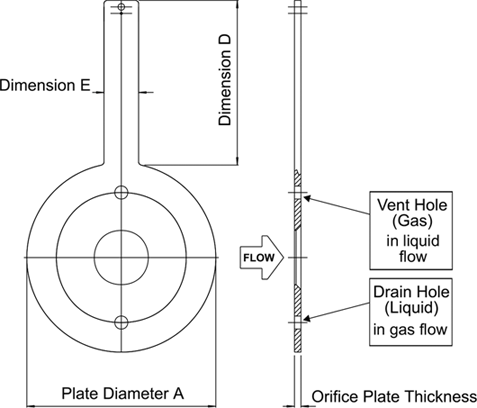

Orifice Plates

Orifice plates are frequently employed when a pump supplies a greater pressure than what is needed by a system. In such cases, an orifice plate is installed in the discharge line to create backpressure, which guarantees that the pump functions within its optimal range. Orifice plates can also be utilized to regulate flow. The orifice plate directs the liquid or gas whose flow rate is to be assessed, resulting in a pressure drop across the plate that fluctuates according to the flow rate. This differential pressure between the outlet and inlet sections is then measured.

| Nominal Line Size | 150 LB | 300 LB | 400 LB | 600 LB | 900 LB | 1500 LB | 2500 LB | |||||||||||||||

| mm | IN | A | D | E | A | D | E | A | D | E | A | D | E | A | D | E | A | D | E | A | D | E |

| 15 | 02-Jan | 47.6 | 125 | 25 | 54 | 125 | 28 | 54 | 125 | 28 | 54 | 125 | 32 | 63.5 | 125 | 28 | 63.5 | 125 | 32 | 69.9 | 125 | 32 |

| 20 | 04-Mar | 57.2 | 125 | 32 | 66.7 | 125 | 32 | 66.7 | 125 | 32 | 66.7 | 125 | 32 | 69.9 | 125 | 32 | 69.9 | 125 | 32 | 76.2 | 125 | 32 |

| 25 | 1 | 66.7 | 125 | 32 | 73 | 125 | 32 | 73 | 125 | 32 | 73 | 125 | 32 | 79.4 | 125 | 32 | 79.4 | 125 | 32 | 85.7 | 150 | 32 |

| 30 | 1 1/4 | 76.2 | 125 | 32 | 82.6 | 125 | 32 | 82.6 | 125 | 32 | 82.6 | 125 | 32 | 88.9 | 125 | 32 | 88.9 | 125 | 32 | 104.8 | 150 | 32 |

| 40 | 1 1/2 | 85.7 | 125 | 32 | 95.3 | 125 | 32 | 95.3 | 125 | 32 | 95.3 | 125 | 32 | 98.4 | 125 | 32 | 98.4 | 125 | 32 | 117.5 | 150 | 32 |

| 50 | 2 | 104.8 | 125 | 32 | 111.1 | 125 | 28 | 111.1 | 125 | 28 | 111.1 | 125 | 28 | 142.9 | 150 | 32 | 142.9 | 150 | 32 | 146 | 150 | 32 |

| 65 | 2 1/2 | 123.8 | 125 | 32 | 130.2 | 125 | 32 | 130.2 | 125 | 32 | 130.2 | 125 | 32 | 165.1 | 150 | 32 | 165.1 | 150 | 32 | 168.3 | 150 | 32 |

| 80 | 3 | 136.5 | 125 | 32 | 149.2 | 125 | 32 | 149.2 | 125 | 32 | 149.2 | 125 | 32 | 168.3 | 150 | 32 | 174.6 | 150 | 32 | 196.9 | 150 | 32 |

| 100 | 4 | 174.6 | 150 | 32 | 181 | 150 | 32 | 177.8 | 150 | 32 | 193.7 | 150 | 32 | 206.4 | 150 | 32 | 209.6 | 150 | 32 | 235 | 150 | 32 |

| 125 | 5 | 196.9 | 150 | 32 | 215.9 | 150 | 32 | 212.7 | 150 | 32 | 241.3 | 150 | 32 | 247.7 | 150 | 32 | 254 | 150 | 32 | 279.4 | 175 | 32 |

| 150 | 6 | 222.3 | 150 | 32 | 250.8 | 150 | 32 | 247.7 | 150 | 32 | 266.7 | 150 | 32 | 288.9 | 150 | 32 | 282.6 | 150 | 32 | 317.5 | 175 | 32 |

| 200 | 8 | 279.4 | 150 | 32 | 308 | 150 | 32 | 304.8 | 150 | 32 | 320.7 | 150 | 32 | 358.8 | 175 | 32 | 352.4 | 175 | 32 | 387.4 | 175 | 32 |

| 250 | 10 | 339.7 | 150 | 32 | 362 | 150 | 32 | 358.8 | 150 | 32 | 400 | 150 | 32 | 435 | 175 | 32 | 435 | 175 | 32 | 476.3 | 200 | 32 |

| 300 | 12 | 409.6 | 150 | 32 | 422.3 | 150 | 32 | 419.1 | 150 | 32 | 457.2 | 150 | 32 | 498.5 | 175 | 32 | 520.7 | 175 | 32 | 549.3 | 200 | 32 |

| 350 | 14 | 450.9 | 150 | 32 | 485.8 | 150 | 32 | 482.6 | 150 | 32 | 492.1 | 150 | 32 | 520.7 | 175 | 32 | 577.9 | 175 | 32 | - | - | - |

| 400 | 16 | 514.4 | 150 | 32 | 539.8 | 150 | 32 | 536.6 | 150 | 32 | 565.2 | 150 | 32 | 574.7 | 200 | 32 | 641.4 | 200 | 32 | - | - | - |

| 450 | 18 | 546.1 | 175 | 32 | 593.7 | 175 | 32 | 587.4 | 175 | 32 | 609.6 | 175 | 32 | 635 | 200 | 32 | 701.7 | 200 | 32 | - | - | - |

| 500 | 20 | 603.3 | 175 | 32 | 650.8 | 175 | 32 | 644.5 | 175 | 32 | 679.5 | 175 | 32 | 695.3 | 200 | 32 | 752.5 | 200 | 32 | - | - | - |

Tab Handled Orifice Plates

- Design to BS 1042

- Range of Orifice Types

- Concentric Square Edge

- Conical Entrance

- Quarter Circle

- Segmental

- Eccentric

- Orifce sizing on request

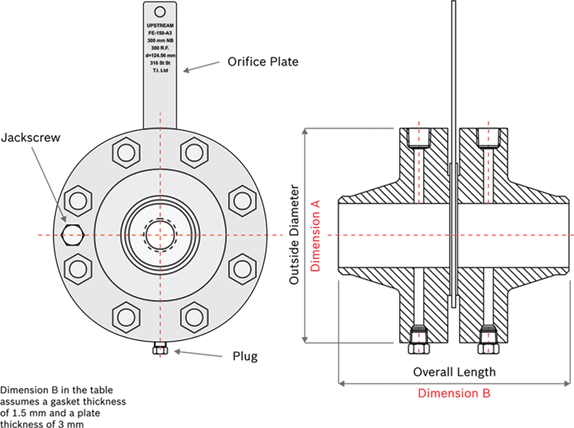

Dimensions

The outside diameter of the orifice plate is equal to the bolt circle diameter of the connecting flanges minus the diameter of the bolt. This ensures that the plate is centered accurately in the line.

Plate thicknesses depend on line size and differential pressure, and should be sufficient to prevent the plate from bending under operating conditions. Recommended plate thicknesses are shown below.

Flometriq Orifice plates can be made in accordance with customer drawings as required.

| Pipe Diameter | Standard Plate Thickness (mm) for Differential Pressure DP | ||

| DP = 250 mbar |

DP = 251 - 500 mbar |

DP = 501 - 2500 mbar |

|

| D < 150 mm | 3 | 3 | 3 |

| 200 < D < 250 | 3 | 3 | 6 |

| 300 < D < 500 | 6 | 6 | 10 |

| 600 < D < 900 b < 0.5 b > 0.5 |

10 6 |

10 10 |

12 12 |

Materials

Standard material grades include 316 Stainless Steel, 304 Stainless Steel, 310 Stainless Steel, Hastelloy® C276, Hastelloy® B3, Duplex Stainless Steel, Super Duplex Stainless Steel, Monel® 400, Carbon Steel, Titanium, Incoloy® 800, Incoloy® 825, Inconel® 600, Inconel® 625, Tantalum, PTFE and PVDF.

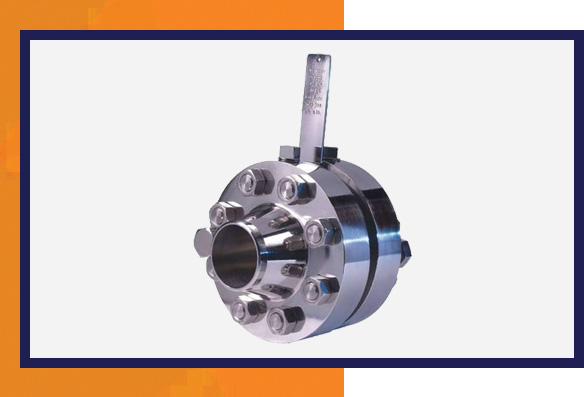

Restriction Orifice Plates

- Manufactured generally to BS 1042

- Wide Range of Materials

- Orifice sizing on request

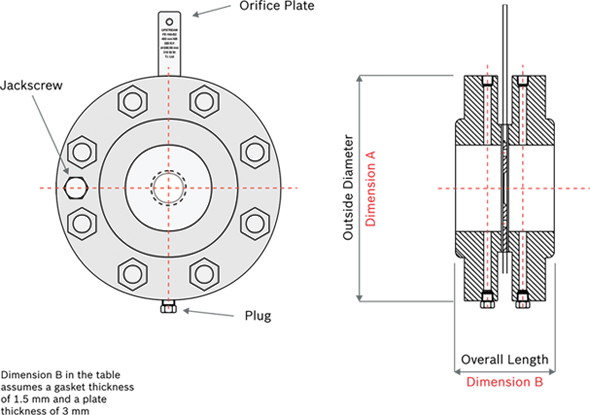

Dimensions

The outside diameter of the orifice plate is equal to the bolt circle diameter of the connecting flanges minus the diameter of the bolt. This ensures that the plate is centered accurately in the line.

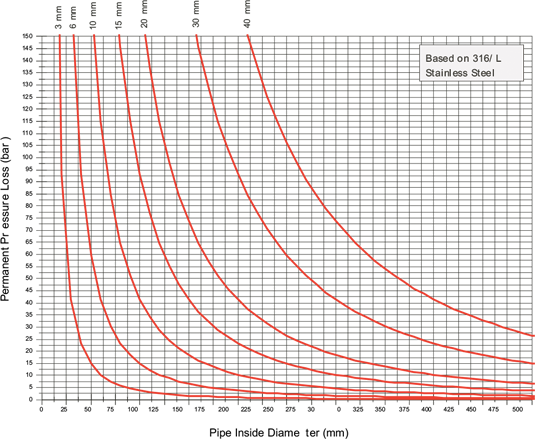

Plate thicknesses depend on line size and differential pressure, and should be sufficient to prevent the plate from bending under operating conditions. Recommended plate thicknesses are shown in the graph below.

PI Controls Europe Orifice plates can be made in accordance with customer drawings as required.

Materials

Standard material grades include 316 Stainless Steel, 304 Stainless Steel, 310 Stainless Steel, Hastelloy® C276, Hastelloy® B3, Duplex Stainless Steel, Super Duplex Stainless Steel, Monel® 400, Carbon Steel, Titanium, Incoloy® 800, Incoloy® 825, Inconel® 600, Inconel® 625, Tantalum, PTFE and PVDF.