Reactor Vessels Provider | Gulf Oil & Gas International

Gulf Oil & Gas International supplies Reactor Vessels for industrial and energy-sector projects, supporting customers in the UAE and export markets with engineering-focused sourcing and project coordination.

Product Overview

Design | Engineering | Manufacturing | Export – Gulf Oil & Gas International, UAE

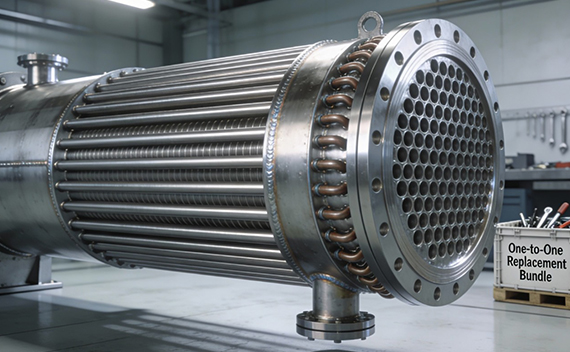

Gulf Oil & Gas International (GOI), UAE, supplies high-performance Reactor Vessels engineered in collaboration with our principal manufacturer, delivering precision-built solutions tailored to project-specific process requirements. From initial design to final pressure testing, each reactor vessel is manufactured under a controlled quality system to ensure safety, efficiency, and durability.

Product Description

Our reactor vessels are designed to support industrial, continuous, and catalytic chemical processes, enabling efficient reaction control and high product yield. The design process begins with detailed engineering drawings, ensuring accurate tolerances, optimized geometry, and compliance with operating conditions.

Each reactor vessel is meticulously designed, fabricated, inspected, and pressure-tested in accordance with ASME standards. The result is a robust, reliable pressure equipment solution capable of operating safely in aggressive chemical and thermal environments.

Design & Engineering Capabilities

- Process-optimized internal design for efficient heat transfer and mixing

- Engineered for high pressure and high temperature service

- Custom nozzle orientation, supports, internals, and agitation provisions

- Designed to minimize operating costs while maximizing reaction efficiency

- Full compliance with ASME BPVC and applicable international codes

Manufacturing & Quality Assurance

- Fabrication under strict quality control procedures

- Material traceability and controlled welding processes

- Non-destructive testing (NDT) and dimensional inspection

- Hydrostatic and pneumatic pressure testing

- Complete documentation and certification package

Materials of Construction

Reactor vessels are available in a wide range of materials based on service conditions and process media:

- Carbon Steel (various grades)

- Stainless Steel (various grades)

- Low Alloy Steel

- HIC + NACE compliant materials

- HIC + NACE with SS 316L Cladding

- LTCS (Low Temperature Carbon Steel) with impact testing up to –45°C

Key Features & Benefits

- Long service life with minimal maintenance

- High resistance to corrosion and thermal stress

- Cost-effective and reliable operation

- Designed for safety, pressure integrity, and process stability

- Suitable for harsh industrial and refinery environments

Typical Applications

Oil Refineries and Hydrocarbon Processing Units

Chemical and Petrochemical Plants

Catalytic and Thermal Reaction Systems

Continuous and Batch Chemical Processing

Why Gulf Oil & Gas International, UAE?

- Trusted designer, supplier, and exporter of ASME reactor vessels

- Strategic collaboration with an experienced principal manufacturer

- Strong expertise in EPC and industrial project execution

- Global supply capability from UAE to GCC, Middle East, Africa, and international markets

- Technical support from design to delivery