Pressure Vessels & Process Equipment Provider | Gulf Oil & Gas International

Gulf Oil & Gas International supplies pressure vessels and process equipment for industrial and energy-sector projects, supporting customers in the UAE and export markets with engineering-focused sourcing and project coordination.

Gulf Oil & Gas International, UAE is a trusted supplier and exporter of ASME Compliant process equipment, offering a comprehensive range of Pressure Vessels, Heat Exchangers, Columns, Towers, Reactor Vessels, Storage Tanks, Condensers, Tube Bundles, and Tonners for Ammonia, Propane, Iso-Butane, Refrigerant, and Chlorine services. We work with authorized principal manufacturing partners holding ASME “U” Stamp, ISO 9001:2015, and ISO 14001:2015 certifications to ensure global compliance, safety, and performance.

Featured Products:

- Industrial Condensers

- Distillation Columns & Towers

- Tube Bundles for Shell & Tube Heat Exchangers

- ASME-Compliant Pressure Vessels & Storage Tanks

- Heat Exchangers

- Reactor Vessels

- Ammonia Service Tonners – Industrial Pressure Vessels

- Tonners for Iso-Butane and Propane Service

- Tonners for Refrigerant Services

- Tonners for Chlorine Service

Serving Oil & Gas, Refineries, Petrochemicals, Fertilizers, Chemicals, Pharmaceuticals, Caustic, and Power industries, our equipment is engineered for severe service applications and manufactured in accordance with ASME, API, TEMA, BS, PESO (CCOE), and Boiler Regulations.

With proven expertise in engineering, design, procurement, manufacturing, inspection, supply, and export, Gulf Oil & Gas International delivers custom-engineered, high-performance process equipment with assured quality, reliability, and on-time delivery for projects worldwide.

Comprehensive Product Range

We offer a diverse portfolio of process equipment tailored to client-approved designs and international codes, serving critical applications across the energy, petrochemical, and industrial sectors.

Advanced Design Capabilities

- Licensed PVElite Software: Industry-standard mechanical design using licensed PVElite, compliant with ASME Section VIII Div.

- Thermal Design Excellence: Advanced thermal design leveraging collaboration with HTRI member organizations to optimize heat transfer and performance

- Multi-Standard Compliance: Expertise across ASME, TEMA, API, Boiler Regulations, and international standards

Gulf Oil & Gas International (GOI), UAE, offers a high-performance range of industrial condensers designed to meet the demanding requirements of modern process industries. In collaboration with our principal manufacturer, we supply and export condensers engineered for efficient heat transfer, reliable condensation, and long-term operational durability.

Our condensers are widely deployed across chemical & intermediate plants, fertilizer units, food and dairy processing facilities, organic batch processing industries, and petrochemical applications, where consistent thermal performance and corrosion resistance are critical.

Designed to operate reliably even in harsh industrial environments, these condensers help improve process efficiency while minimizing maintenance and operational downtime.

With flexible material configurations, customized designs, and proven manufacturing quality, Gulf Oil & Gas International delivers condenser solutions tailored to specific process conditions, ensuring energy efficiency, safety, and extended service life.

Key Highlights

- High-efficiency heat transfer and reliable condensation performance

- Suitable for chemical, fertilizer, food & dairy, batch processing, and petrochemical industries

- Manufactured using premium materials for corrosion resistance and durability

- Customizable designs to match process and operating requirements

- Energy-efficient operation with reduced maintenance costs

- Backed by experienced principal manufacturer and global supply capability

Gulf Oil & Gas International (GOI), UAE, offers high-performance distillation columns and towers designed to deliver efficient and reliable separation processes for a wide range of industrial applications. In collaboration with our principal manufacturer, we supply and export columns engineered for multi-pressure, atmospheric, and vacuum operating conditions, ensuring optimal performance across diverse process requirements.

Our distillation columns are widely used in chemical processing, petrochemicals, refineries, fertilizers, pharmaceuticals, and specialty industries, where precision, durability, and operational stability are critical.

Designed with robust construction and premium materials, these columns ensure long service life, high separation efficiency, and reduced maintenance.

With customizable designs, flexible material options, and proven engineering expertise, Gulf Oil & Gas International delivers cost-effective and industry-compliant distillation solutions tailored to specific plant requirements.

Key Highlights

- High-efficiency separation and distillation performance

- Suitable for pressurized, atmospheric, and vacuum service

- Manufactured using premium and corrosion-resistant materials

- Custom-engineered designs for process optimization

- Durable construction for long service life and low maintenance

- Supported by experienced principal manufacturer and global supply capability

Design, Engineering, Supply & Export – Gulf Oil & Gas International, UAE

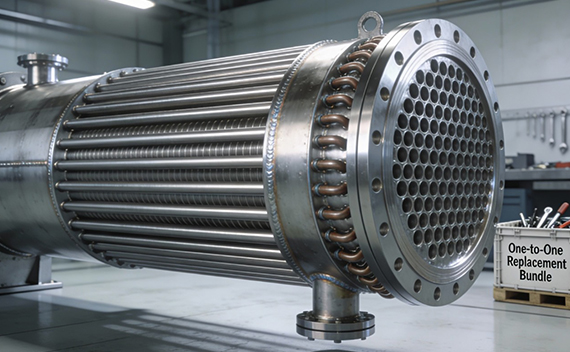

Gulf Oil & Gas International (GOI), UAE, offers high-performance tube bundles for shell and tube heat exchangers, engineered for efficient heat transfer, mechanical stability, and long-term operational reliability. In collaboration with our principal manufacturer, we design, supply, and export tube bundles for both new heat exchangers and one-to-one replacement applications, ensuring seamless integration into existing systems.

Tube bundles represent the core heat transfer assembly of shell and tube heat exchangers, directly influencing thermal efficiency, pressure drop, vibration control, and overall equipment life. Our tube bundles are precision-engineered to operate under high pressure, high temperature, corrosive, and cyclic thermal conditions, making them ideal for critical process industries.

Design & Engineering Capabilities

Our tube bundles are designed to suit a wide range of shell & tube heat exchanger configurations, including:

- Fixed Tube Sheet designs for stable and high-pressure applications

- Floating Head designs enabling thermal expansion and ease of maintenance

- Kettle Type configurations optimized for condensing and cooling services

- Expansion Bellows assemblies (thin-wall and thick-wall) to accommodate thermal cycling

- One-to-one replacement tube bundles for shutdowns, revamps, and turnaround projects

Advanced baffle arrangements ensure controlled shell-side fluid flow, enhanced heat transfer, and effective mitigation of flow-induced tube vibration, improving exchanger reliability and service life.

Gulf Oil & Gas International (GOI), UAE, offers a comprehensive portfolio of ASME-compliant pressure vessels, storage tanks, and process equipment engineered for safe and reliable operation in high-pressure, high-temperature, and critical service environments. In collaboration with our principal manufacturer, we design, fabricate, supply, and export custom-built vessels for oil & gas, chemical, petrochemical, power, fertilizer, and process industries worldwide.

Our pressure vessel solutions are developed with a strong emphasis on safety, precision engineering, and strict compliance with ASME Compliant and international pressure vessel codes. Each vessel is engineered to deliver maximum structural integrity, operational reliability, and long service life under extreme operating conditions.

Key Highlights

Our tube bundles are designed to suit a wide range of shell & tube heat exchanger configurations, including:

- ASME BPVC-compliant pressure vessels & storage tanks

- Custom-engineered process columns and specialized pressure equipment

- Proven solutions for extreme pressure, temperature, and corrosive service

- Wide metallurgical range including clad and lined constructions

- Large-diameter and heavy-wall vessel manufacturing capability

- Backed by experienced principal manufacturer and global supply capability

High-Performance ASME-Compliant Heat Exchangers Custom-Engineered Shell & Tube Heat Exchangers | Design, Supply & Export

Gulf Oil & Gas International (GOI), UAE supplies and exports custom-engineered Shell & Tube Heat Exchangers for Oil & Gas, Petrochemical, Chemical, and Process industries worldwide. Developed with authorized principal manufacturing partners, our solutions combine advanced thermal and mechanical design with precision Tube Bundle fabrication to ensure high efficiency and long service life.

Designed for severe operating conditions, our heat exchangers comply with ASME Compliant, TEMA, BS, IS, DIN, and ISO standards, with provisions for wind and seismic loads, delivering reliable and safe performance across demanding industrial environments.

Key Highlights

- Wide range of Shell & Tube, Regenerative, Fluid, Waste Heat Recovery, and Phase-Change Heat Exchangers

- Optimized for high-temperature, high-pressure, and corrosive service

- Durable, corrosion-resistant construction for long service life

- Designed to minimize downtime and maintenance costs

- Fully customizable for process-specific requirements

ASME Code Compliant | High-Pressure & High-Temperature Process Equipment

Gulf Oil & Gas International (GOI), UAE, offers custom-engineered Reactor Vessels designed, supplied, and exported in collaboration with our principal manufacturer, meeting the most demanding requirements of the oil & gas, chemical, petrochemical, and process industries.

Our reactor vessels form a critical part of pressure vessels and process equipment systems, engineered to safely handle high-pressure chemical reactions, catalytic processes, and extreme operating conditions. Designed in accordance with ASME Compliant and international pressure vessel codes, each reactor delivers superior performance, safety, and long-term reliability.

Reactor Vessel Capabilities

- Engineered for high-pressure and high-temperature chemical processes

- Suitable for continuous, batch, and catalytic reactor applications

- Designed to integrate seamlessly with process columns, towers, and downstream systems

- Optimized for operational efficiency, reaction yield, and process stability

Design Code & Compliance

- The ammonia tonners are engineered and manufactured in strict accordance with IS 2825 – Class 1 (1969) with the latest amendments and fully comply with the applicable Gas Cylinder Rules, ensuring regulatory acceptance and operational safety. Each tonner undergoes 100% radiographic examination of the shell and heads to guarantee structural integrity, with inspection carried out by Lloyd’s (TPIA) or an authorized client representative. To enhance mechanical strength and long-term reliability, the vessels are subjected to stress relieving and mandatory Post Weld Heat Treatment (PWHT) as per approved design and quality requirements.

- The ammonia tonners are designed for safe and reliable service with a wide range of industrial gases and refrigerants, including Ammonia (NH₃), R22, R134A, R404A, R407C, R290, and R600A. This broad media compatibility makes them highly suitable for ammonia refrigeration systems, cold storage plants, chemical processing units, and industrial gas handling applications, ensuring flexibility, safety, and operational efficiency across diverse industries.

High-Power, ASME & IS-Compliant Tonners | Design, Supply & Export – Gulf Oil & Gas International, UAE

Gulf Oil & Gas International (GOI), UAE, in collaboration with our principal manufacturer, offers a distinguished range of high-performance Tonners for Iso-Butane and Propane Service, designed to meet the most stringent industry standards.

These tonners combine safety, durability, and ease of handling, making them the preferred choice for industrial applications handling flammable gases and refrigerants.

Product Highlights

- Designed for safe storage and handling of Iso-Butane, Propane, and other industrial gases

- Robust and durable construction for long service life

- Ergonomically engineered for user-friendly handling and operational efficiency

- Fully compliant with IS 2825 – Class 1 (1969) latest amendments and Gas Cylinder Rules

- Suitable for high-pressure industrial applications across oil & gas, chemical, and refrigeration sectors

- Inspected and certified by Lloyds (TPIA) / Client representatives

These tonners deliver reliable performance, operational safety, and cost-effectiveness, helping industries maintain efficient workflows with minimal downtime.

High-Performance Refrigerant Tonners | ASME & Gas Cylinder Code Compliant – Gulf Oil & Gas International, UAE

Gulf Oil & Gas International (GOI), UAE, in collaboration with our principal manufacturer, offers a premium range of high-power Tonners for Refrigerant Services, engineered for safe, durable, and reliable storage and handling of industrial refrigerants such as R32 and R410A.

These tonners are designed for industrial refrigeration, HVAC, and chemical processes, ensuring optimal safety, durability, and operational efficiency.

Product Highlights

- Compliant with ASME Section VIII, Div.1 (Ed.2010, Add.2011) and Gas Cylinder Rules 2004

- High-pressure tonners engineered for industrial refrigerants

- Robust, corrosion-resistant construction for long service life

- User-friendly design for easy handling and operational efficiency

- Certified and inspected by Lloyds (TPIA) to ensure safety and reliability

- Ideal for refrigeration systems, chemical processes, and industrial gas handling

These tonners deliver enhanced performance, safety, and cost-effectiveness, minimizing downtime and maximizing operational efficiency.

High-Performance Chlorine Tonners | ASME & Industrial Code Compliant – Gulf Oil & Gas International, UAE

Gulf Oil & Gas International (GOI), UAE, in collaboration with our principal manufacturer, offers a premium range of high-power Tonners for Chlorine Service, engineered for safe, reliable, and long-term handling of industrial chlorine. These tonners are ideal for chemical, water treatment, and industrial applications, ensuring operational safety and compliance with international standards.

Our Chlorine Tonners combine robust durability, user-friendly handling, and enhanced safety, making them a preferred choice for industries worldwide.

Key Highlights

- ASME Section VIII Div.1 and Bhor 1968 compliant design

- High-pressure tonners suitable for industrial chlorine storage and handling

- Robust, corrosion-resistant construction for long service life

- User-friendly design for safe handling and operational efficiency

- Certified inspection by Lloyd’s Register Industrial Service

- Optional enhancements such as emergency KIT B compatibility, protective coatings, and additional accessories

These tonners deliver enhanced performance, safety, and cost-effectiveness, minimizing downtime and maximizing operational efficiency.