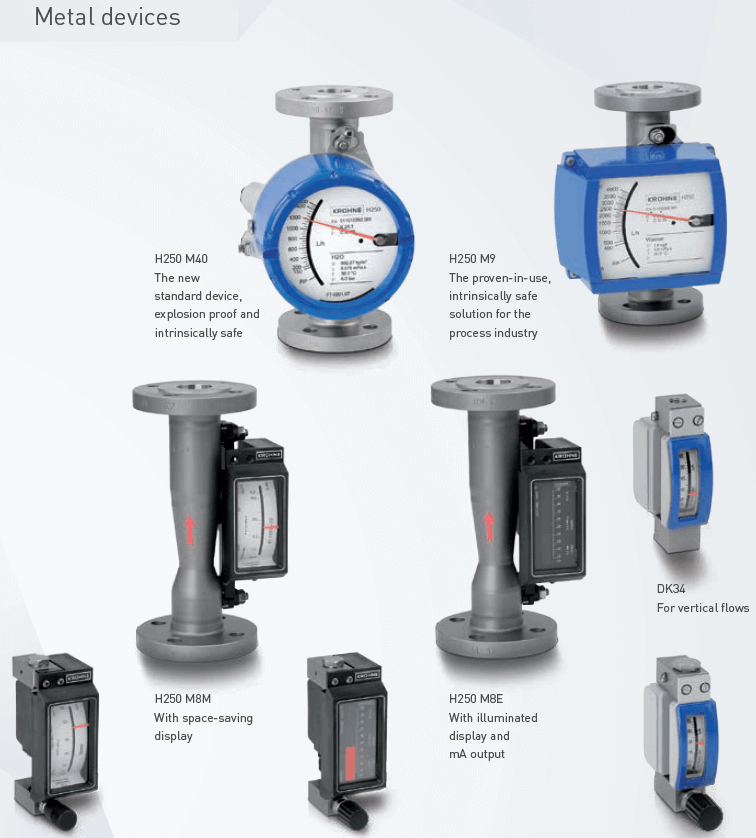

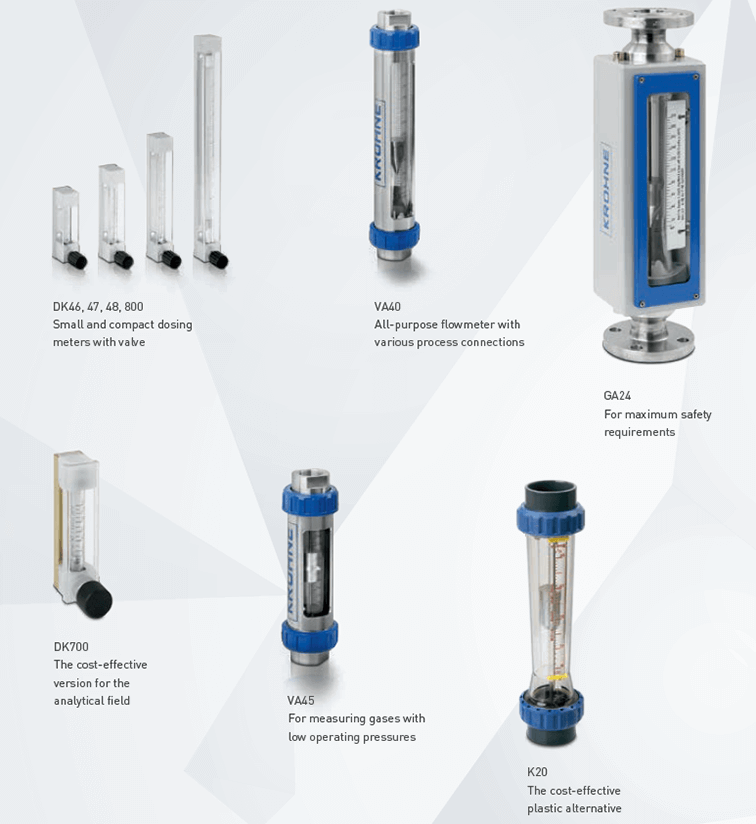

Krohne Metal Tube and Glass Tube Variable Area Flowmeters

- Model No.H250

- TypeVariable Area Flow Meter

- CetificationISO

- MediumGas, Liquid, Steam, Oil

- Accuracy1.6%

- Protection CategoryIP65, 66 , 67; NEMA4, 4X, 6

- Process ConnectionsDN15…150 , 1/4" NPT, 1/2" NPT, G1/4

- Pressure RatingsPN16, 40, 63, 100, 160, 250*

- Temperature Ranges-40…+200°C;

- ApprovalsATEX

- Power Supply:12…30 VDC, None

- DisplayDie Cast Aluminium, Polyurethane Coating

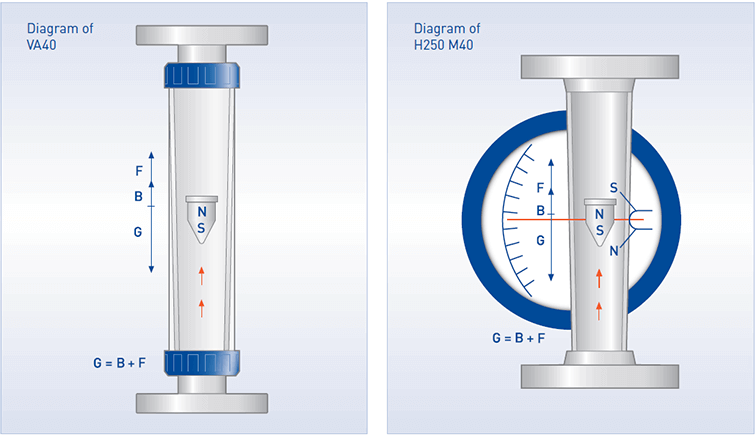

Variable area flowmeters are suitable for the measuring of clean liquids and gases. They consist of upright conical tube made of metal, glass or plastic, in which a sophisticated float moves freely up and down. The flow goes through the tube, which is applied from the bottom to top, causes the float to rise until the forces are in equilibrium.

- Three forces are acting on the float:

- The buoyancy force B, which depends on the density of the medium and the volume of the float.

- The gravity force G, which depends on the mass of the float.

- The flow force F which depends on the float shape and the flow velocity through the variable area between float and tube.

Every flow rate corresponds to a defined variable area resulting from the conical shape of the measuring tube and the specific position of the float. With glass cones, the flow value can be read directly from a scale at the level of the float. With metal cones, the float position is transmitted to an indicator by magnetic means. There is no need for auxiliary power. Different measuring ranges are realised through variations in cone sizes and shapes and in selecting different float shapes and materials.

- Measurement and dosing of additives such as catalysts, surfactants, foam and corrosion inhibitors, caustic soda, chlorine or sulphur substances, etc.

- Inerting of tanks or containers

- Measurement and dispensing of rinsing mediums (purge meters)

- Sample feed measurement for analyser systems

- Dosing and monitoring of lubricants and coolants for bearings and seals for process pumps and rotating machinery

- Hygienic applications in the food and pharmaceutical industries

- Measurement of gases and chemicals in laboratories and test facilities

- Gas/oil burner consumption measurement

For over 30 years, KROHNE has been a reliable partner for nuclear power plant operators and system builders. In this field, KROHNE meets the requirements of KTA 1401, RCC-E, RCC-M and ASME Section III. This authorizes us to mark products with the N stamp and NPT stamp.

-

Maximum reliability when measuring liquids and gases – Since 1921 Industries:

- Chemical

- Petrochemical

- Mechanical and plant engineering

- Offshore plants

- Pharmaceutical

- Food and beverage

- Water and wastewater

- Power plants Measuring

- Our Focus

- Oilfield|Refinery|Petrochemical|Marine|Power|Process|Industrial