Gulf Oil and Gas International with its rich manufacturing experience offers handheld ultrasonic flow meter. It is designed to measure the fluid velocity of liquid within a closed conduit. This is done by using clamp-on sensors which non-intrusively generate and receive ultrasonic waves. It measures liquid flow rate by calculating the difference between transit time of ultrasonic wave downstream and upstream of liquid.

Easy Installation

Easy Installation Reduced Installation Time

Reduced Installation Time Improved Installation accuracy

Improved Installation accuracy No need to Cut/Obstruct the flow

No need to Cut/Obstruct the flow No pressure Loss

No pressure Loss

It comes with easy to install user friendly installation kit

Installation Kit primarily Consist of following items

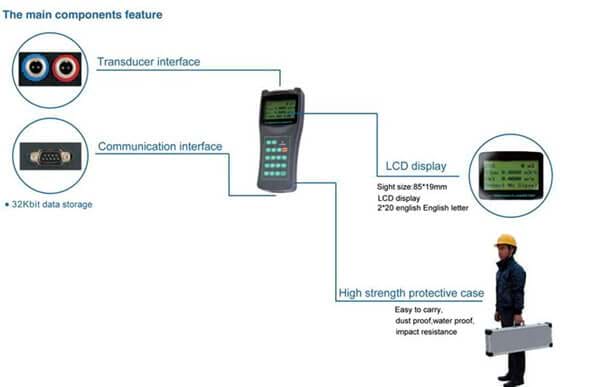

RS 232 Interface

RS 232 Interface RS 485 Interface

RS 485 Interface HART compliant for communication with any HART field device

HART compliant for communication with any HART field device

Ultrasonic Flow Meters over Mechanical Flow Meters

Non-intrusive measurement

Ultrasonic flow meters don't require direct contact with the fluid, eliminating the need for cutting pipes or installing flow obstructions.

Data logging and connectivity

Ultrasonic flow meters often have built-in data logging and connectivity options for trend analysis and integration with control systems.

High accuracy and repeatability

Ultrasonic flow meters provide precise measurements across a wide range of flow conditions.

Low maintenance requirements

Ultrasonic flow meters have no moving parts, resulting in minimal maintenance needs and longer service life.

Bi-directional flow measurement

Many ultrasonic flow meters can measure flow in both directions, accommodating applications with bi-directional flow.

Improved energy efficiency

Ultrasonic flow meters have lower pressure drop, consuming less energy to operate.

Ultrasonic flow meters can handle various fluids, flow rates, and pipe sizes without modifications.

Water Supply

Water Supply

Supply Heating

Supply Heating

Building Energy Conservation

Building Energy Conservation

Metallurgy

Metallurgy

Petroleum & Chemical

Petroleum & Chemical

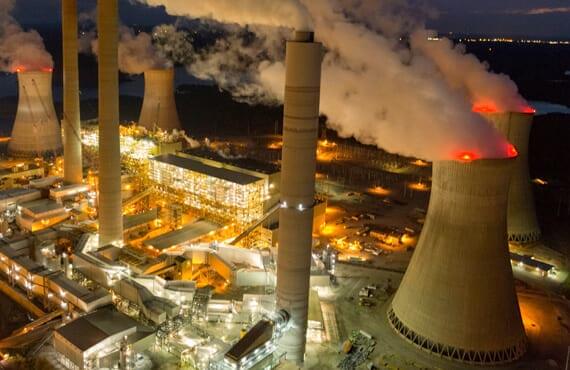

Power Plant

Power Plant

Marine

Marine

Oil field

Oil field